New Catalog

Download our Cleanroom Catalog

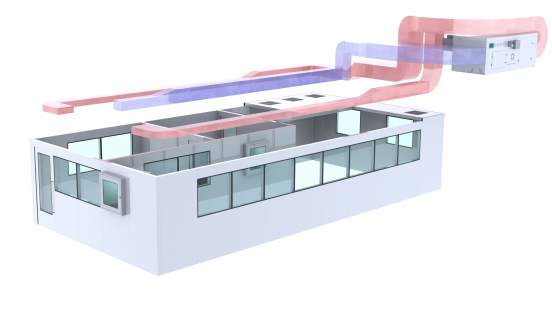

DownloadClean Room Ventilation System – HVAC

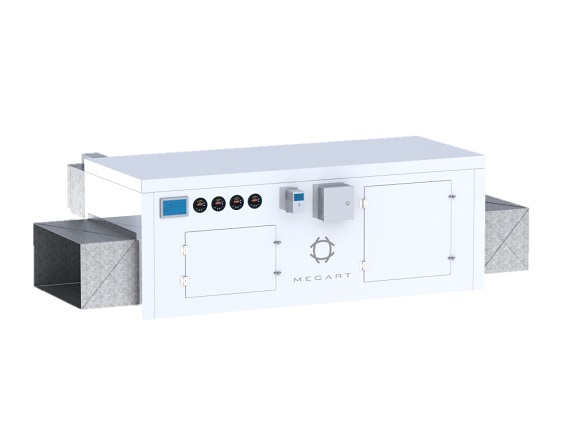

With years of experience in cleanroom manufacturing and hundreds of successfully completed projects, Mecart can design and supply the best clean room HVAC units, meeting both your requirements and your budget.

Since the clean room HVAC air handling units are at the heart of your clean room, it should not be taken lightly. With our experienced in-house engineering team, Mecart will analyze all the aspects of the clean room ventilation system in order to design and build you a comfortable cleanroom that exceeds your requirements.

HVAC stands for Heating, Ventilation and Air Conditioning. It is a general term for indoor environmental comfort, which creates indoor air quality (air change per hour, CFM, temperature and humidity).

When it comes to cleanroom HVAC systems, it means a lot more than comfort. The cleanroom air handling system controls the temperature and the humidity to your appropriate levels of precision, similar to standard HVAC. In addition to comfort, cleanroom HVACs differentiate themselves from conventional systems with their increased air supply, airflow patterns, use of high efficiency clean room filters and room pressurisation. The increased air supply brings more air changes per hour with new HEPA filtered air circulating into the cleanroom many times per hour.

Clean room HVAC designs involve knowledge of regulations, cleanliness level guidelines, airflow, room pressurisation, temperature control, humidity control and accounting of activities taking place inside.

Don’t worry, our cleanroom experts do.

Whether you need temperature/humidity control precision, specific air flow, have space constraints, or any other specific requirements, let Mecart design your clean room air handling unit to meet your specifications.

If you are already working with your preferred HVAC contractor/supplier, Mecart can supervise the integration into its cleanroom design. We can also outsource your specified HVAC unit and manage the installation and commissioning.

FFUs are an alternative to HVAC systems in a less stringent ISO class of clean rooms. FFUs are often used in projects with height restrictions, rather than HVAC systems where the installation of makeup air ducts and recirculating air needed require much more space. FFU configuration is often a cost effective option, if you don’t need to cool your room (low heat gain), since it uses the air directly from the main building. This eliminates the need for a second ceiling above your cleanroom to create a plenum.

Generally, FFUs cannot create pressure head as strong as the air handling unit (AHU) and build a cascade of positive pressure. Another thing to consider is the noise generated by the fan inside the FFUs (just above your head). For large cleanrooms with many FFUs, this noise can become an issue.

Our in-house acoustical specialist can simulate FFUs usage to help you select the most appropriate option for your clean room project.

Get a state-of-the-art, long-term asset that exceeds your requirements and expectations.

By continuing to use the site you agree to our privacy policy.

I agree