How Classification Impacts the Design of a Cleanroom

Clients often come to us specifically requesting an “ISO 7 cleanroom” or an “ISO 8 cleanroom.” What they often fail to realize is that the ISO class does not define the layout of the cleanroom. It only defines the cleanliness level that needs to be met. In fact, the ISO classification actually corresponds to a specification of how clean the cleanroom must be. The ISO 14464-1 standard doesn’t say how to design the cleanroom, it only specifies the maximum quantity of air particles allowed.

In order to help people that may be less familiar with cleanroom terminology and standards, below you’ll find some cleanroom design elements which are impacted by cleanroom classifications.

What is cleanroom classification?

A cleanroom’s class is determined by the concentration of particles of various sizes ranging from 0.1 microns to 0.5 microns, which is determined by ISO 14644-1.

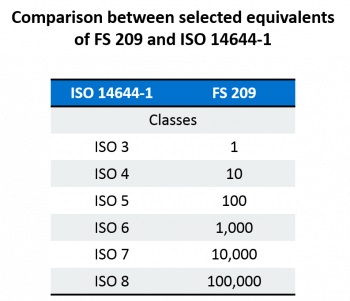

The ISO standard 14644-1 (ISO 5, 6, 7, 8) replaced the Federal Standard 209 classification (Class 100; Class 10,000; Class 100,000) in 1999 (and revised in 2015), but many companies continue to use the traditional Class 100; Class 10,000; Class 100,000 terminology.

You might also like this article —>Cleanroom Classifications (ISO 8, ISO 7, ISO 6, ISO 5)

1) The layout and the quantity of classified rooms

The cleanroom classification will influence the layout of a facility. For example, you can enter an ISO 8 cleanroom directly from an uncontrolled environment. On the other hand, you will need at least one airlock (my recommendation is two) before entering an ISO 6 environment. It is important to keep this in mind when planning your space.

2) The HVAC system

A cleanroom isn’t simply walls and ceilings. The heart of the cleanroom is the air treatment system (HVAC). Cleanroom HVACs differ from conventional systems with their increased air supply, airflow patterns, use of high efficiency filters, and room pressurization. In order to meet the required air cleanliness, the air must pass through HEPA filters. The lower the ISO class, the more often you will need to pass the air through the HEPA filter. This is what we call air change per hour (ACH). Thus, the HVAC’s required air flow (cubic feet per minute (CFM)) is calculated using the ACH and room volume.

2.1) Air changes per hour (ACH)

In order to reach a desired cleanliness level inside the cleanroom, the HVAC system combines air changes per hour (ACH) with HEPA filtered air circulating into the cleanroom many times per hour. The required ACH is determined by the ISO class to be met, as illustrated below. In comparison, a conventional HVAC system usually makes two to four air changes per hour, whereas in a cleanroom it can range anywhere from 10 to 250 or even more.