New Cleanroom Design Calculator Tool

In the article How Classification Impacts the Design of a Cleanroom which was written for R&D Magazine, we explained how to determine the required CFM, the quantity of HEPA filters, and the quantity of low air returns in a cleanroom. To simplify this even more, we created a tool that estimates it for you. You don’t need to crunch the numbers yourself anymore. You can simply use our brand new cleanroom calculator tool! Simply input the answers for each classified room you have.

What can you determine with our cleanroom calculator tool?

- Total airflow in cubic feet per minute (CFM) needed for the cleanroom project

- Air changes per hour (ACH) per classified room (ISO 8, ISO 7, ISO 6, ISO 5)

- Quantity of low air returns

- Quantity of HEPA filters

- Quantity of lighting fixtures

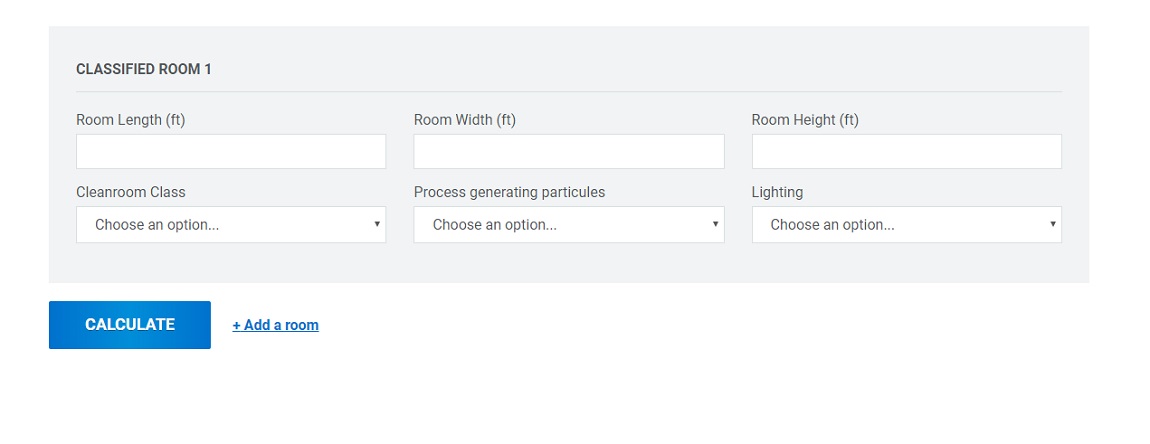

How can you use the cleanroom calculator tool?

For every classified room (ISO 8, ISO 7, ISO 6, ISO 5) in your cleanroom project (anteroom/gowning room, clean zone, etc.), complete a separate row in the table with:

- Room length (ft)

- Room width (ft)

- Room height (ft)

- Cleanroom class (ISO 8, ISO 7, ISO 6, ISO 5)

- Process generating particles

- Lighting level

Same ISO Class Cleanroom, but different size

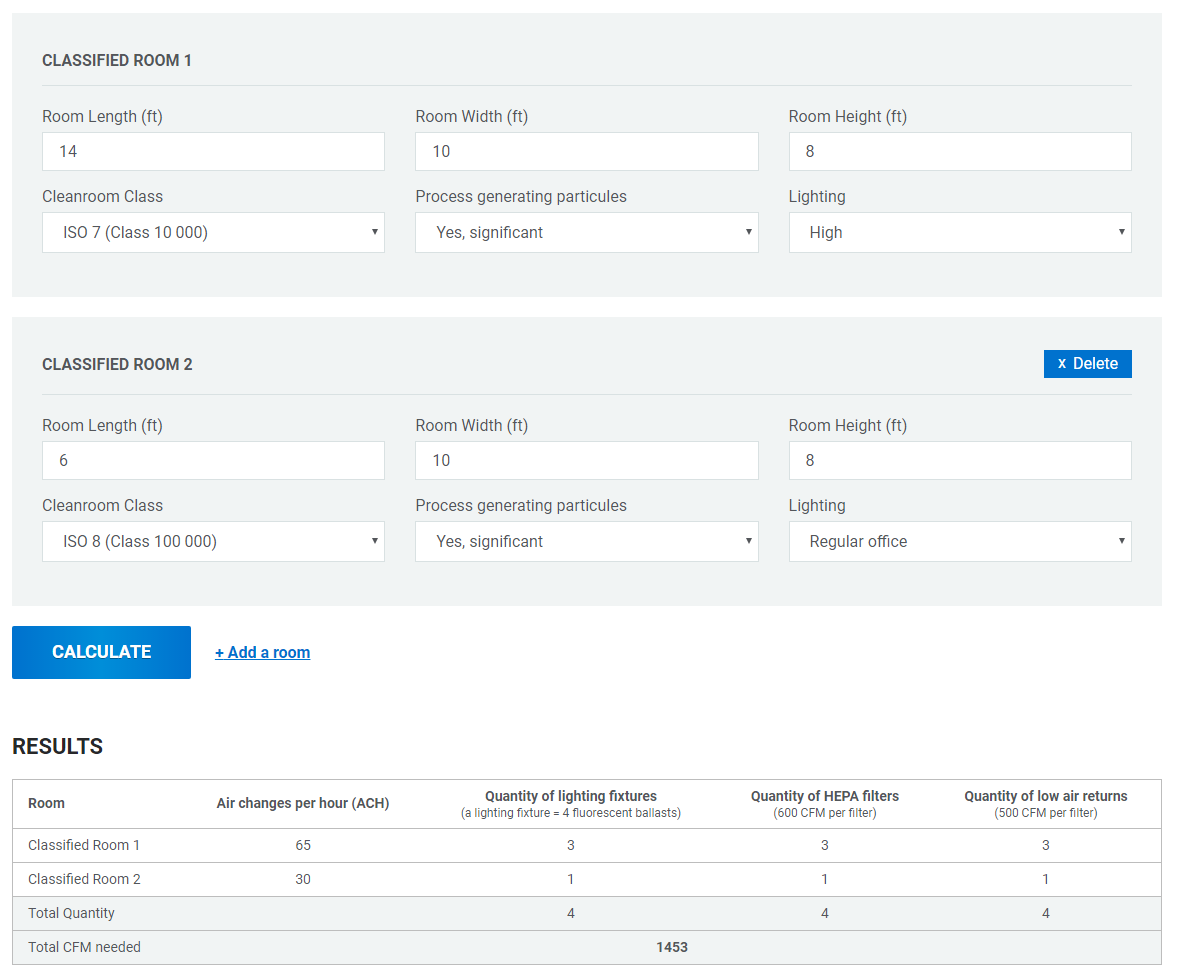

- Small 14’ x 10’ ISO 7 cleanroom with a 6’ x 10’ ISO 8 anteroom

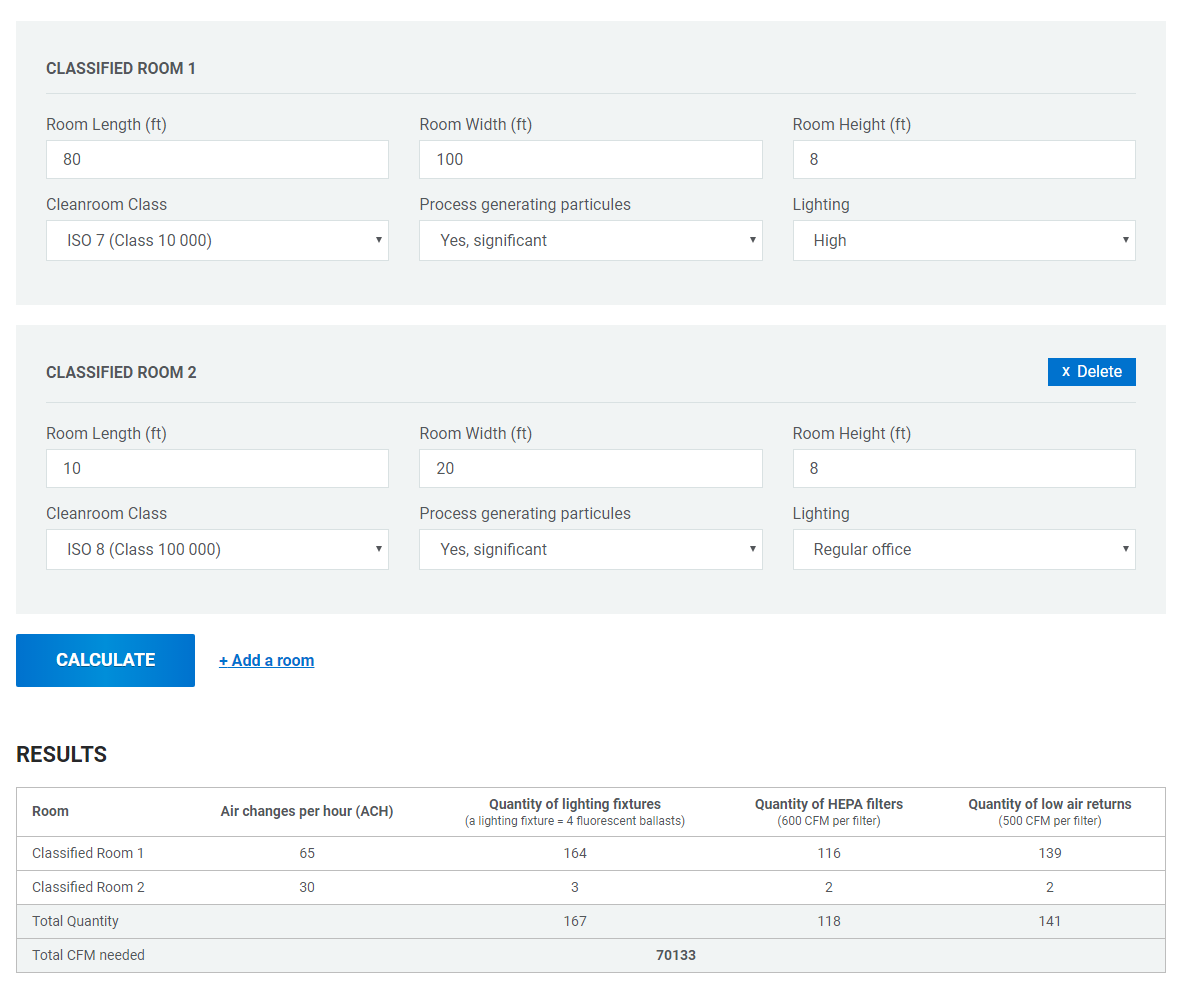

- Large 80’ x 100’ ISO 7 cleanroom with a 10’ x 20’ ISO 8 anteroom

1) Small 14’ x 10’ ISO 7 cleanroom with a 6’ x 10’ ISO 8 anteroom

2) Large 80’ x 100’ ISO 7 cleanroom with a 10’ x 20’ ISO 8 anteroom

Here is an example for a 55′ x 35′ cleanroom with the Cleanroom Design Calculator

CURIOUS TO SEE HOW IT WORKS?

Take it for a spin to see how much you can save time and ease your cleanroom calculations.

Other factors to consider when designing a cleanroom

There are other aspects you should consider that influence the design and the price of a cleanroom.

- Cleanroom ISO classification

- Size

- Using a fume hood, biosafety cabinet or other equipment

- Monitoring system for temperature, humidity, differential pressure, and for particles

- Space and location

- Utilities and access panels

- Full flush vs semi flush windows

Finally, to be ready to kickstart your cleanroom project, be ready to answer the following questions:

- Which class, regulation or other standards must you comply with?

- What are the required operating conditions in the cleanroom?

- Do you have a sketch of the cleanroom you are considering?

- Will you be using a fume hood or biosafety cabinet?

- What space will you be working with? Do you have easy access to the space? What floor is it on? Do you have a shipping dock?

Disclaimer

Please note, this calculator is a simple tool. You should always request a detailed calculation from an HVAC cleanroom specialist!

Several crucial aspects are not accounted for in the calculation, such as:

- The number of people working in the cleanroom

- The equipment, furniture, and supplies inside the cleanroom (since they may generate air particulates and contamination)

- Heat gain

- The movement of people and material in and out of the cleanroom

- The pressure differential

- Temperature and humidity

The calculator is also only suitable for positive pressure cleanrooms. It is not suitable for a negative pressure cleanroom.

Curious to see how it works?

Take it for a spin to see how much you can save time and ease your cleanroom calculations.