Challenge: Complex Sterile Manufacturing Expansion

Pillar 5 Pharma required a new filling suite to expand their sterile manufacturing capabilities for ophthalmic eye drops and solid dosage tablets. The project presented several key challenges:

- Last-Minute Project Takeover: MECART assumed project responsibility from a previous vendor at the eleventh hour, requiring rapid adaptation and seamless integration of services to meet the customer’s deadline.

- Strict cGMP Compliance: A cleanroom designed to meet stringent cGMP and ISO 14644-1:2015 standards.

- Customization and Integration: A cleanroom specifically engineered to accommodate customer-specified equipment, including—but not limited to—an autoclave, touch-free access stations, iris pass-throughs, and Roxstek outputs.

- Adaptation and Problem-Solving: MECART adapted designs in real time, modifying pass-throughs, reconfiguring wall layouts—including a removable wall with a detachable door—and creating a specialized autoclave room to meet evolving project demands.

- Mezzanine Dismantling: The safe removal of a mezzanine adjacent to an active cleanroom was completed without any disruption to ongoing production.

Partnering with MECART allowed us to rapidly expand our sterile manufacturing capabilities while maintaining the highest quality and compliance standards. Their modular solution and expert team were instrumental in overcoming the unique challenges of this project.

MECART’s Solution: Customization and Rapid Deployment

MECART’s modular cleanroom system provided the flexibility and rapid deployment needed to meet Pillar 5 Pharma’s requirements.

- Modular Construction: MECART’s modular panels allowed for quick and efficient installation, minimizing disruption to Pillar 5 Pharma’s operations.

- Advanced HVAC and Airflow: MECART implemented a sophisticated HVAC system, including desiccant wheel technology, to maintain precise environmental control and meet Class A/B/C/D cleanliness levels.

- Specialized Autoclave Room: MECART designed and built an insulated room specifically for an autoclave installation, featuring enhanced air exchange capabilities.

- Adaptive Solutions: MECART adapted pass-throughs to prevent trolley movement between rooms and modified wall configurations to increase air return capacity and accommodate the autoclave installation.

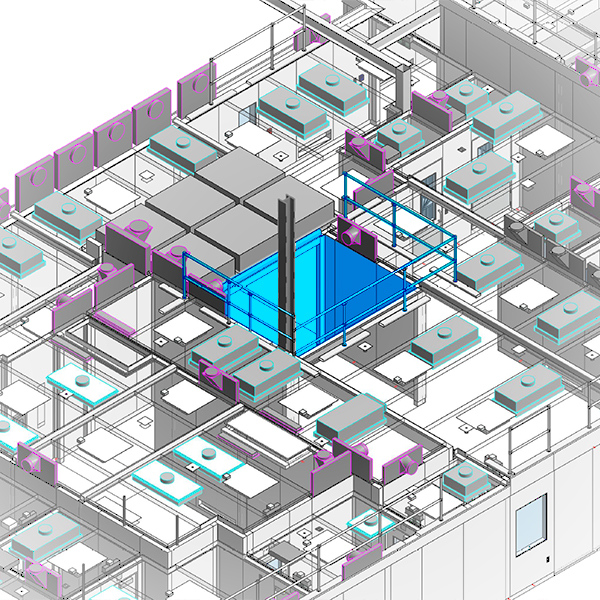

- Self-Supporting and Walkable Ceiling: This two-level walkable ceiling was engineered to allow multiple operational heights within the production spaces. Such a layout required significant coordination work between Pillar5, trades and engineering groups to design a structure able to support these loads, that remained concealed inside the cleanroom panels, that allowed openings for extraction of heat gains from important equipment, while blending within a complex architectural layout.

- Integrated Utilities: All essential utilities, including electrical, communication systems, and process piping, were seamlessly integrated within the cleanroom walls, ensuring a clean, uncluttered environment and facilitating easy maintenance.

Results: Enhanced Sterile Manufacturing Capabilities

The completed cleanroom provides Pillar 5 Pharma with a state-of-the-art facility that supports their mission of producing high-quality sterile ophthalmic eye drops and solid dosage tablets. The cleanroom’s key benefits include:

- Expanded Production Capacity: The facility enables Pillar 5 Pharma to efficiently produce a higher volume of sterile products.

- Improved Quality Control: The controlled environment minimizes the risk of contamination, ensuring the safety and quality of the pharmaceutical products.

- Increased Efficiency: The main autoclave was seamlessly integrated into a dedicated service space, concealing structural elements of the main building, redirecting equipment heat outside the cleanroom, and streamlining smoother transitions between production zones—enhancing sterile workflow without compromising environmental control.

- Flexibility and Adaptability: The modular design allows for future expansion or modification as Pillar 5 Pharma’s needs evolve.

- Adherence to Regulatory Standards: Met all stringent GMP and ISO 14644-1:2015 requirements.

- Optimized Space and Accessibility: The self-supporting and walkable ceiling design maximized usable space and facilitated maintenance.

- Clean and Organized Environment: Integrated utilities within the walls created a clean, organized, and easily maintainable workspace.

Partner with MECART for your Cleanroom needs