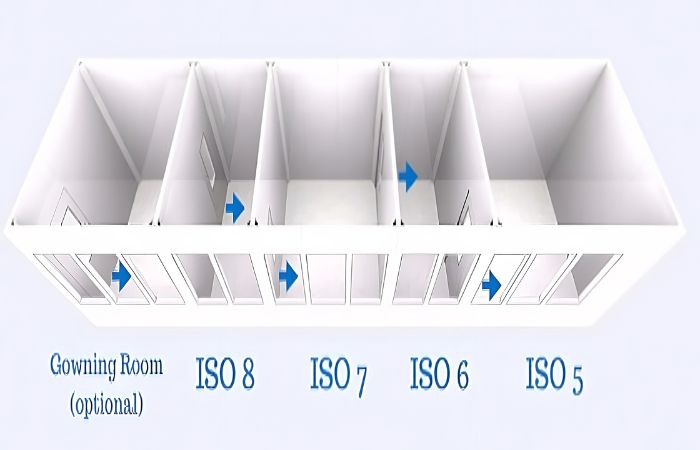

The FS209E cleanroom classification system has six cleanroom cleanliness classes: Class 1, Class 10, Class 100, Class 1,000, Class 10,000, and Class 100,000. ISO 14644-1 replaced FS209E in 1999 for Europe and in 2001 for the United States. The ISO classification adds two cleaner standards and one dirtier standard for a total of nine classifications. To learn more about ISO standards, read our article Cleanroom Classifications (ISO 8, ISO 7, ISO 6, ISO 5).

The cleanroom given names under Federal Standard 209e are:

- Class 100,000 clean room (dirtiest)

- Class 10,000 clean room

- Class 1,000 clean room

- Class 100 clean room

- Class 10 clean room

- Class 1 clean room (cleanest)

Despite the obsolescence of the FS209E classifications, the terms and names used for cleanrooms continue to be used in popular language as references, especially in specific industries such as the semiconductor sector.

This article aims to demystify the nuances between the FS209E and the ISO 14644-1 standard and to help you better understand the details and requirements of the former cleanroom classification system.

To learn more about cleanroom classifications, read our featured articles:

- Clean Room Classifications (ISO 8, ISO 7, ISO 6, ISO 5)

- Building a GMP Facility: 8 GMP Cleanroom Requirements

- GMP Facility: Understanding Grade A, Grade B, Grade C & D

Cleanroom Classifications and Particles Count

By definition, cleanrooms are classified based on how clean the air is. The maximum number of particles allowed varies depending on the cleanroom classifications you wish to obtain.

Inside 209E cleanrooms, the particles equal to and greater than 0.5µm are measured in 1 cubic foot of air, whereas ISO classes are in cubic meters of air.

Below is the graphic chart showing the maximum particle count for the Federal Standard 209E and its ISO standards equivalent.

Class 100000, class 10000, class 1000 – Non-Unidirectional Air Flow Classes

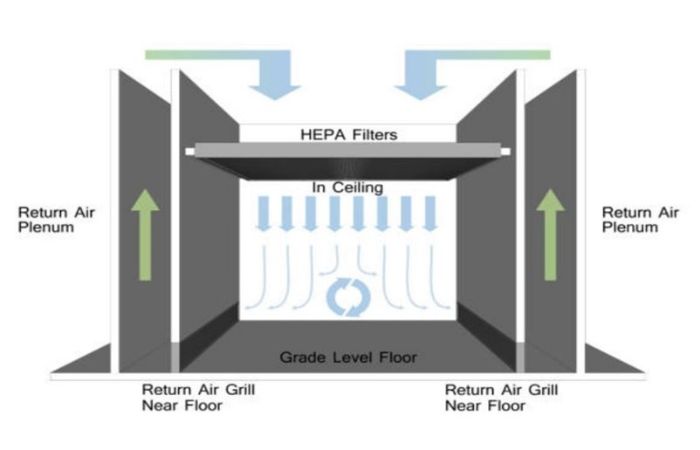

Class 100,000, Class 10,000, and Class 1,000 can be attained with either non-unidirectional or unidirectional airflows. However, as unidirectional airflow cleanrooms are more expensive, we do not advocate them in this instance. A non-unidirectional airflow will be sufficient for achieving these classifications.

Class 100000 Clean Room / 100K Clean Room

Class 100,000 cleanroom is the “dirtiest” class and the last cleanroom class of the FS209E standards. The ISO equivalent of the 100K cleanroom is an ISO 8.

They are also used for anteroom, gowning areas, and background zones for Class 10,000 cleanrooms.

Non-unidirectional airflow cleanrooms are ideal for attaining Class 1,000, Class 10,000, and Class 100,000 (ISO 8) cleanliness levels.

Like the 10K classification, Class 100,000 cleanrooms are numerous on the market and one of the most frequently used around various sectors for less stringent cleanroom operations.

Here are some of the industries in which Class 100,000 cleanrooms are used:

- Medical device

- Electronics and Semiconductors

- Pharmaceutical

- Cosmetics

- Aerospace

- Automotive

- Vinyl Printing

Class 100,000 cleanroom projects completed by MECART:

Class 10000 Clean Room / 10K Clean Room

When converted to ISO standards, a Class 10,000 clean room (also known as a 10K cleanroom) is similar to an ISO 7 cleanroom.

Class 10,000 cleanrooms are one of the most common, if not the most common, level of cleanliness across the industry.

It is used for multiple applications in various sectors, such as:

- Biotechnology

- Semiconductors

- Nanotechnology

- Sterile compounding

- Medical device manufacturing

- Clinical research

This is the second dirtiest cleanroom environment and the penultimate level of cleanliness, according to federal 209E standards.

Class 10,000 (ISO 7) production conditions can be achieved in cleanrooms with non-unidirectional airflow.

Class 10,000 cleanroom projects completed by MECART:

- Class 10,000 Clean Room for SMT Manufacturing in a Semiconductor Fab

- Medical Device Manufacturing Clean Room – 20,000 SQFT

- Clinical Manufacturing Facility for Cell and Gene Therapy – CGMP Cleanroom

- Clinical Trials – Drug Development Cleanrooms

- cGMP and Biotech Cleanroom for Stem Cell Manufacturing – Theranostics

Class 1000 Clean Room / 1K Clean Room

Class 1,000 cleanrooms, or 1K cleanrooms, are equivalent to an ISO 6 cleanroom environment.

With a maximum of 10,000 airborne particles below 0.5 micrometers permitted per cubic foot, they are also the fourth cleanest environment, according to federal 209E standards.

Class 1,000 (ISO 6) cleanrooms are a more frequently used classification of cleanrooms than Classes 1, 10, and 100.

A Class 1,000 is therefore used in a variety of industries and application types, such as:

- Medical device manufacturing

- Electronics manufacturing

- Sterile compounding

- Aerospace product manufacturing

- Cosmetics production

Class 1,000 (ISO 6) does not require employment of an unidirectional airflow system but can, depending on the layout of the room.

Class 1,000 (ISO 6) production conditions can be achieved with non-unidirectional airflow.

Class 1,000 cleanroom projects completed by MECART:

Class 100 Clean Room / Class 100 Cleanroom

A Class 100 cleanroom can allow a maximum of only 100 particles smaller than 0.5 micrometers per cubic foot, making it the third most clean environment, according to the FS209E classification.

Its equivalent ISO grade for cleanliness is an ISO 5 cleanroom environment.

Although Class 100 cleanrooms are more common than Class 1 and Class 10, this is still a rigorous classification to achieve.

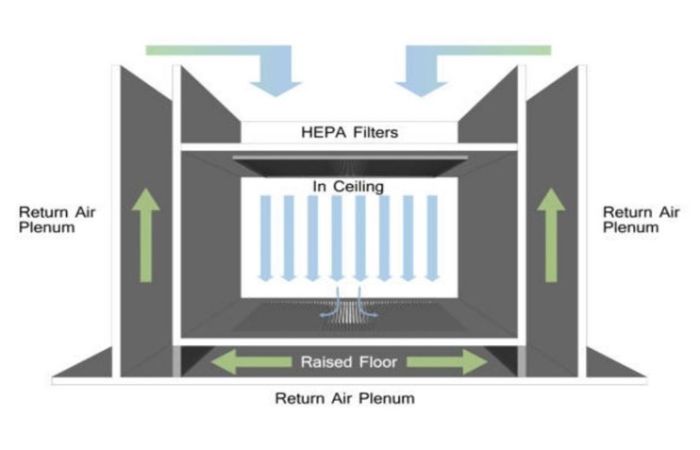

Class 100 (ISO 5) cleanrooms or lower cleanliness classifications, according to FS209E (or ISO), should be achieved by implementing a unidirectional airflow and adding a ventilated raised floor system.

The raised floor system is a crucial part of the airflow design and process, as the panels and perforated grids provide optimal laminar airflow while also being used to reduce conductivity and static electricity issues for certain cleanroom applications.

Class 100 cleanrooms are used in biotechnology, pharmaceuticals, and nanotechnologies.

Cleantech companies often use Class 100 cleanrooms for manufacturing applications such as:

- High-purity fine chemicals for industrial use and research

- Ion lithium batteries for electric vehicles

- Solar panel manufacturing

- Active medical devices

Class 100 cleanroom projects completed by MECART:

Class 10 Cleanroom

According to the previous 209E Federal Standards, a Class 10 cleanroom is the second highest level of cleanliness. This level of cleanliness is equivalent to an ISO 4 room under the ISO 14644-1 standard.

For the Class 10 cleanroom, the maximum number of particles with a diameter of 0.5 micrometers per cubic foot is 10.

Class 10 cleanrooms (ISO 4) are commonly used for nanotechnology, semiconductor, and control areas in biotechnology and pharmaceutical applications for filling lines and other critical areas.

If you want to achieve Class 10 (ISO 4), you must use unidirectional airflow and a ventilated raised floor to remove more airborne particles.

In cleanrooms with unidirectional airflow, filtered air is continually driven downward and recirculated via perforated raised floor panels, ensuring excellent laminar airflow.

Class 1 Clean Room / Class 1 Cleanroom

Class 1 cleanrooms were the cleanest cleanroom class under the outdated FS209E classifications. The level of cleanliness for a Class 1 cleanroom is equivalent to an ISO 3 room, as stated by the ISO 14644-1 standard.

The FS209E classes were named after the number of airborne particles permitted per cubic foot inside a cleanroom with a reference particle diameter of 0.5 micrometers.

For the Class 1 cleanroom, it can contain only 1 particle with a diameter of 0.5 micrometers per cubic foot.

Few processes necessitate this level of cleanliness. Class 1 cleanrooms (ISO 3) are necessary only for the most sterile procedures. For example, some semiconductor manufacturing or handling operations require a Class 1 cleanroom (ISO 3).

If you want an operating cleanroom to reach a Class 1 (ISO 3), you must employ unidirectional airflow in combination with a ventilated raised floor to remove more of the airborne particles that are created.

With unidirectional airflow cleanrooms, filtered air is constantly directed downward, passing through perforated raised floor panels to be recirculated, providing optimum laminar airflow.

Please note that this information is provided for educational purposes only. The definitions in this article are oversimplified to assist with understanding.

This article will not help you decide which cleanroom classification you must reach. If help is needed in this respect, seek the advice of an expert in your industry (pharmaceutical, medical devices, sterile compounding, electronics, etc.).

Sources: